Product Description

The PG SPARK OES Metal Analyser is widely used for chemical composition analysis of Irons and Steels, Aluminum, Copper, Nickel, Cobalt, Magnesium, Titanium, Zinc, Lead, Tin, Silver and other metals and alloys.

PG Spark CCD Optical Emission Spectrometer uses a high-resolution linear CCD to perform full-spectrum scanning from 130-900nm. The PG Spark also benefits from an intelligent argon controlled flushed spectrometer chamber system thus ensuring maximum stability for long periods of analysis and the use of analytical wavelengths unconstrained. This includes analysis for elements such as Carbon, Nitrogen, Sulphur, Arsenic, Boron and Phosphorus at ultra-low levels.

Key Applications

- Large Steel Plants where needs are at about 10ppm for elements such as C, N, Cr, S, P

- Pure Metal applications for purity of metals such as Al, Cu, Pb, Zn, Mg, Ti etc.

- Testing Laboratories, Commercial testing Labs, Small Foundries etc.

- Regulatory compliance for very low limits of detection such as Pb, As, Cd.

- Foundries which need a fast, accurate and precise analysis from materials in the production furnaces.

- Analysis of non ferrous alloys such as Aluminium. Copper, Lead, Tin, Titanium, Silver etc.

- Warehouse material identification

- Manufacturing facilities.

Optical System – Spectrometer Layout with CCD and Channel Electronics.

- Paschen Runge Mounted Spectrometer

- Spectral Range 130-800nm

- Focal length of Spectrometer is 500mm

- Holographic Grating with 2700 lines/mm (Elements such as N, B, P, S, Li, Na and K can be analysed)

- Dispersion in the first order is 0.74nm/mm and 0.37nm/mm in the second order

- Resolution: 0.005926nm

- Not limited by elemental channels

- Detector with multiple CCD’s

- Spectrometer uses a constant temperature system with a control accuracy of ± 0.10C

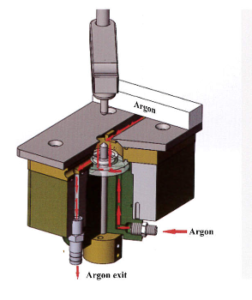

Programmable Control Argon-Flushes Spectrometer Chamber

- The Spectrometer Optical Chamber is a NEW optical chamber with an extremely low thermal expansion coefficient which provides high instrument stability.

- The argon flush to the Spectrometer chamber is programmed and controlled via the software.

- The warm-up time for a ‘cold’ machine which has been shut down for 12 hours or more is ONLY 30 minutes. For a system in operation the start time is 5 minutes or less.

Argon Consumption

- Argon Flow Rate during analysis is under 8 litres/minute

- Argon Flow during standby is 60ml/min

- The flow, pressure and the rate of flow are all programmed via the software

CCD Detector

- High Resolution CCD Detector

- 3648 single chip CCD Pixels

- Single Pixel size of 8µm

Spark Stand

The spark stand will take a maximum weight of 50Kg of sample. The Spark Stand has been specifically designed coaxial stand with an optimised internal gas circuit which greatly reduces argon consumption. The sample cavity is cleaned by a Self Purging Function

Schematic Drawing of Spark Stand and a series of sparks on a steel sample.

Spark Excitation Source

- Discharge Parameters protected by Passwords.

- Maximum Discharge Frequency – 1000Hz.

- Maximum time before adjustment is 5000 hours

- Self-purging function that keeps the cavity clean.

- Newly designed co-axial spark stand with an optimised internal gas circuit which greatly reduces argon consumption.

Software

- Calculation of the same element in different matrices using stored calibrations.

- Material Identification

- Support automatic calculation functions such as Carbon Equivalent.

- NET based port data acquisition’ means communication between OES readout system and control pf PC via Ethernet TCP/IP ?

- Re-calibration by 1 single sample possible.

- The software is available in different languages namely English, German, Spanish, Russian and Chinese.

Basic Specifications and Environment requirements for PG Spark CCD-OES Spectrometer

| Power Supply | 220v ± 10%, single phase 16A 2.5KVA |

| Outline Dimensions | 840L x 470W x 440H |

| Weight | Approx. 80Kg |

| Operating Environment | Temperature 10-500C

Humidity less than 75% |

| Argon Purity | ≥99.999% |