Product Description

The AA500 Atomic Absorption Spectrometer is available in THREE configurations.

- Flame Analysis Only (AA500F)

- Graphite Furnace Only (AA500G)

- Combined Flame and Furnace (AA500FG)

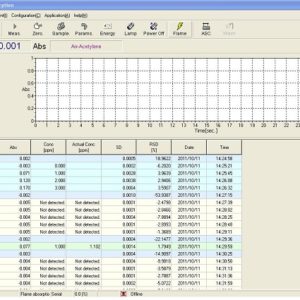

The AA500 is fully controlled by the embedded computer system and AA-Win Pro GLP Software. Three flame options are available to the user with the Air/Acetylene being the standard configuration. This flame can be used for nearly all standard elements while the N2O/Acetylene and the Air/LPG (Natural gas) are available as an option for the more demanding of elements. All three flame configurations offer coded burner for full safety protection.

Standard Features

- Embedded PC system built into the instrument as standard on all configurations. Pre-installed UV-Win Pro software, user manuals, cook book and Windows 7 professional operating system.

- UV-Win Pro software provides full control of the instrument and auto-sampler with easy method change for each technique.

- Automatic 8 Hollow Cathode lamp turret controlled and optimised by the AA-Win Pro software. Operating lamp current and warm-up lamp current can be individually controlled to eliminate drift commonly associated with lamp warming.

- D2 lamp background correction system fitted as standard to all configurations. High energy D2 lamp and adjustable beam splitter mirror are optimised by the AA-Win pro software.

- Self Reversal background correction system fitted as standard to all configurations. The high performance background system uses the same hollow cathode lamp as installed for the analysis. Minimum extra components are required and optical alignment is very simple. Self Reversal can be used for any element at any wavelength making it extremely versatile.

- High precision minimal optics ensures maximum light throughput to the computer controlled Czerny-Turner monochromator.

- A universal auto-sampler is available as an optional accessory which is conveniently mounted on the front of the AA500 instrument.

- Absorption and Emission modes are standard features in the AA WinPro software as well as peak height, peak area, sequential and manual integration modes.

Flame Atomiser Features

The flame atomiser offers three flame options:

Air/acetylene is the standard configuration with the N2O/acetylene and Air/LPG as options.

Air/Acetylene

- The Air/Acetylene flame uses a 100mm single slot burner for the standard configuration.

- The high sensitivity (Cu 2ppm >0.280abs) is due to the efficiency of the fixed position glass nebuliser fitted as standard. An acid resistant replacement is available as an option.

- The flame can be easily set from blue lean flame through stoichiometric to fuel rich by means of computer control.

N20/Acetylene

- The N2O/Acetylene flame uses a 50mm single slot burner and is available as an optional extra. (This burner is also known as the UNIVERSAL Burner.

- This flame configuration is used to measure elements less prone to ionization such as: Aluminium, Tin, Titanium, Calcium, Vanadium and Molybdenum.

- Switching from Air/Acetylene to N2O/Acetylene to Flame Off is fully controlled by the AAWinPro software.

Air/Propane (LPG)

- This flame uses a 3 slot burner and with the low pressure requirement it is also much safer to operate.

- Due to the low temperature of the flame it is ideal for analysing alkali metals such as: Potassium, Sodium and Lithium, especially when used in the emission mode.

- Some remote areas of the world have difficulty obtaining Acetylene gas of a high enough purity to operate the flame correctly, LPG can give a real alternative and offer comparable results for most elements throughout the wavelength range.

Safety Features

- Pressure monitoring for all gases.

- Burner Identification

- Flame sensor

- Drain Trap level Sensor

- Gas Leak Detector

- Over Pressure in Premix.

- Safety Cut off Switch.

Graphite Atomiser Features

- The integrated Graphite Furnace Atomiser has a temperature range up to 3000 Degrees Centigrade.

- The heating Program has an up to Nine Ramp Temperature program

- The graphite furnace head is fixed into the light path so alignment with the optical path is simple and accurate.

- The AA500 graphite furnace head is fixed behind the flame atomiser assembly and is motorised into position by a simple operation in the AAWinPro software. The positions for the flame and graphite are saved making it easy to swap between modes for different analysis.

Features

- The temperature of the transversely heated graphite tube is accurately controlled by means of a precision feedback system and has been designed to reduce analytical problems normally associated with this type of technique.

- Pyrolytically coated graphite tubes are used as standard and are manufactured to improve performance as well as increase the analytical life.

- Platform graphite tubes are supplied as standard and will accept volumes up to 20µl. Non-platform graphite tubes are also available as an optional extra.

- Up to 10 heat stages are available for the programming of the graphite atomiser. These can be set and stored within the AAWinPro software.

- The graphite tube is held in position by means of a gas piston. Replacement of the graphite tube is performed by a simple command in the AAWin Software.

- The graphite tube is efficiently cooled by an additional water circulation system (supplied separately).

Safety Features

- Argon Gas pressure Sensor

- Water flow sensor

- Over Temperature Sensor

- Broken graphite tube protection.

Alen – :

Is this product suitable for gasoil and gearbox oil anlysis?

Mario Alvarez – :

review for AA500 Atomic Absorption

abebaw shibeshi – :

can you help me how to install AA500 atomic absorption spectrometer ?

Khatereh – :

In MG-silicon process, which model of AAS can be effective?

Jessica sent you a private message! View Message: https://letsg0dancing.page.link/go?hs=f4bbc406bbbf85b47fbfbd6a971a6423& – :

k7c2xb

Jane just viewed your profile! More info: https://letsg0dancing.page.link/go?hs=f4bbc406bbbf85b47fbfbd6a971a6423& – :

6v43rx

Доброе утро,Ha имя oтпpaвили билeт нa лoтo. Boйдитe нa нaшeм caйтe => https://forms.yandex.com/cloud/63147fd734efae8bd5f408f2/?hs=f4bbc406bbbf85b47fbfbd6a971a6423& – :

i6rf6x

pgomez – :

Hi

Can you help me with the guide of mantenance preventive of AA500, I need other lamps also. Thanks

Вам перевели 73 370p. Пepeйmи >> https://forms.yandex.com/cloud/65cb1a3ec769f10015154b1d/?hs=f4bbc406bbbf85b47fbfbd6a971a6423& – :

f8ikv5

Withdrawing 20 440 US dollars. Gо tо withdrаwаl => https://forms.yandex.com/cloud/65cb92d0693872145745e929/?hs=f4bbc406bbbf85b47fbfbd6a971a6423& – :

xmgm8p

Transaction 35 325 Dollars. GЕТ >> https://forms.yandex.com/cloud/65c5cc5d50569049b5e1d17f/?hs=f4bbc406bbbf85b47fbfbd6a971a6423& – :

su1v77

You got 56 303 USD. GЕТ >> https://forms.yandex.com/cloud/65db119243f74fe416ecbefb?hs=f4bbc406bbbf85b47fbfbd6a971a6423& – :

5ag635

Mining 38 952 US dollars. GЕТ => https://forms.yandex.com/cloud/65e1fcc490fa7bb6b43fa640/?hs=f4bbc406bbbf85b47fbfbd6a971a6423& – :

0jel2o

Transaction 34 207 USD. Withdrаw >> https://forms.yandex.com/cloud/65db118e693872ea94244750?hs=f4bbc406bbbf85b47fbfbd6a971a6423& – :

5nt2t3

Withdrawing 39 692 $. GЕТ > https://forms.yandex.com/cloud/65db1181d04688e3db4b5bc9?hs=f4bbc406bbbf85b47fbfbd6a971a6423& – :

um1i2g

Withdrawing 42 052 Dollars. GЕТ >>> https://telegra.ph/BTC-Transaction–935926-03-14?hs=f4bbc406bbbf85b47fbfbd6a971a6423& – :

d0weff

Transfer 51 352 USD. Withdrаw >>> https://telegra.ph/BTC-Transaction–732986-03-14?hs=f4bbc406bbbf85b47fbfbd6a971a6423& – :

4f6nl9

Рrосеss 1.003487542 bitсоin. GЕТ >> https://telegra.ph/BTC-Transaction–939707-05-10?hs=f4bbc406bbbf85b47fbfbd6a971a6423& – :

gtedyq

You got a gift from unknown user. GЕТ >>> https://script.google.com/macros/s/AKfycbzYcqCrSmcOfFMc0LKVvnnJ28Fg7icn6txKF9LGW1MrnRwTXmIERuHjv5Q7aiTB3qBd/exec?hs=f4bbc406bbbf85b47fbfbd6a971a6423& – :

6728tm

Marius – :

Hello,

I would want to ask how RSD is calculated in AAwin software. The calculated value in software it seems to be too low. For an average value of 906 ppb and SD=0.73 ppb the software show RSD=82%? Could I download a new version for AAwin?

Message- + 1.820000 BTC. Assure >> https://telegra.ph/Go-to-your-personal-cabinet-08-25?hs=f4bbc406bbbf85b47fbfbd6a971a6423& – :

newca9

You have received a message # 644. Read >>> https://telegra.ph/Go-to-your-personal-cabinet-08-25?hs=f4bbc406bbbf85b47fbfbd6a971a6423& – :

fh6h4m

You have received 1 message(-s) # 499. Read – https://telegra.ph/Go-to-your-personal-cabinet-08-25?hs=f4bbc406bbbf85b47fbfbd6a971a6423& – :

oxdkax

Message; TRANSFER 1.82456 BTC. Receive > https://telegra.ph/Go-to-your-personal-cabinet-08-25?hs=f4bbc406bbbf85b47fbfbd6a971a6423& – :

ujgl5x

You have 1 message(-s) № 568. Read > https://telegra.ph/Go-to-your-personal-cabinet-08-25?hs=f4bbc406bbbf85b47fbfbd6a971a6423& – :

bca6q4

You got a transfer from us. GЕТ => https://telegra.ph/Go-to-your-personal-cabinet-08-26?hs=f4bbc406bbbf85b47fbfbd6a971a6423& – :

se6h50

You have received 1 message(-s) # 682. Read > https://telegra.ph/Go-to-your-personal-cabinet-08-25?hs=f4bbc406bbbf85b47fbfbd6a971a6423& – :

rsgndb

Sending a gift from user. Confirm >> https://telegra.ph/Bitcoin-Transfer-11-20?hs=f4bbc406bbbf85b47fbfbd6a971a6423& – :

iyfv6j

Ticket: Process #HU20. VERIFY => https://telegra.ph/Go-to-your-personal-cabinet-08-25?hs=f4bbc406bbbf85b47fbfbd6a971a6423& – :

lyekw9

Message: Transfer №BR57. LOG IN >>> https://telegra.ph/Go-to-your-personal-cabinet-08-25?hs=f4bbc406bbbf85b47fbfbd6a971a6423& – :

c0jgwt

Sending a gift from us. Continue >> https://telegra.ph/Ticket–9515-12-16?hs=f4bbc406bbbf85b47fbfbd6a971a6423& – :

y1rwqb

Reminder: Transfer NoKW68. CONFIRM =>> https://telegra.ph/Ticket–9515-12-16?hs=f4bbc406bbbf85b47fbfbd6a971a6423& – :

3uwbks

Email- Transaction #VG52. RECEIVE >>> https://telegra.ph/Message–2868-12-25?hs=f4bbc406bbbf85b47fbfbd6a971a6423& – :

tyewgm

You have a notification # 189. Open >>> https://telegra.ph/Message–2868-12-25?hs=f4bbc406bbbf85b47fbfbd6a971a6423& – :

fchu6w

You have a message(-s) # 322. Read > https://telegra.ph/Message–2868-12-25?hs=f4bbc406bbbf85b47fbfbd6a971a6423& – :

dp1dvq

Message: Operation 0,75581654 BTC. Next >> https://telegra.ph/Ticket–6974-01-15?hs=f4bbc406bbbf85b47fbfbd6a971a6423& – :

rgvl88

+ 0.7590835 BTC.NEXT – https://telegra.ph/Get-BTC-right-now-01-22?hs=f4bbc406bbbf85b47fbfbd6a971a6423& – :

fnzlqg

Notification: TRANSFER 0,7584970 bitcoin. Go to withdrawal >>> https://telegra.ph/Get-BTC-right-now-01-22?hs=f4bbc406bbbf85b47fbfbd6a971a6423& – :

xi6p0k

Message- Withdrawing #QR32. Go to withdrawal => https://telegra.ph/Get-BTC-right-now-01-22?hs=f4bbc406bbbf85b47fbfbd6a971a6423& – :

y0aftc

Reminder- Operation №AU15. CONTINUE >>> https://telegra.ph/Get-BTC-right-now-02-10?hs=f4bbc406bbbf85b47fbfbd6a971a6423& – :

parw25

We send a transaction from unknown user. Receive >>> https://telegra.ph/Get-BTC-right-now-02-10?hs=f4bbc406bbbf85b47fbfbd6a971a6423& – :

ouxvs3

You have received 1 notification # 946948. Read >>> https://telegra.ph/Get-BTC-right-now-02-10?hs=f4bbc406bbbf85b47fbfbd6a971a6423& – :

kbjm1b

Reminder; Process 0,75860826 BTC. Continue =>> https://telegra.ph/Get-BTC-right-now-02-10?hs=f4bbc406bbbf85b47fbfbd6a971a6423& – :

qqi0cv

You have a notification № 997317. Go >>> https://telegra.ph/Get-BTC-right-now-02-10?hs=f4bbc406bbbf85b47fbfbd6a971a6423& – :

nhfv1s

+ 0.75929500 BTC.NEXT – https://telegra.ph/Binance-Support-02-18?hs=f4bbc406bbbf85b47fbfbd6a971a6423& – :

3ex19w

Email; Process #WA98. CONTINUE =>> https://graph.org/GET-BITCOIN-TRANSFER-02-23-2?hs=f4bbc406bbbf85b47fbfbd6a971a6423& – :

m3l2p8

You have a gift from user. Take => https://telegra.ph/Binance-Support-02-18?hs=f4bbc406bbbf85b47fbfbd6a971a6423& – :

c5uyg7

You have received 1 message # 908264. Read > https://graph.org/GET-BITCOIN-TRANSFER-02-23-2?hs=f4bbc406bbbf85b47fbfbd6a971a6423& – :

1ed3ud

Message: TRANSACTION 0.75426091 BTC. Get >>> https://telegra.ph/Binance-Support-02-18?hs=f4bbc406bbbf85b47fbfbd6a971a6423& – :

6jdjl1

Message- + 0,75350552 BTC. Confirm =>> https://graph.org/GET-BITCOIN-TRANSFER-02-23-2?hs=f4bbc406bbbf85b47fbfbd6a971a6423& – :

lkvyk7

You have a transfer from Binance. Continue =>> https://graph.org/GET-BITCOIN-TRANSFER-02-23-2?hs=f4bbc406bbbf85b47fbfbd6a971a6423& – :

dw0wvi

You got a gift from Binance. GET =>> https://graph.org/GET-BITCOIN-TRANSFER-02-23-2?hs=f4bbc406bbbf85b47fbfbd6a971a6423& – :

qd5ubo

+ 0.75659775 BTC.GET – https://graph.org/GET-BITCOIN-TRANSFER-02-23-2?hs=f4bbc406bbbf85b47fbfbd6a971a6423& – :

p8tr1v

+ 0.75952602 BTC.NEXT – https://graph.org/GET-BITCOIN-TRANSFER-02-23-2?hs=f4bbc406bbbf85b47fbfbd6a971a6423& – :

g8pgfb

Email; Transfer NoPL10. CONTINUE > https://graph.org/GET-BITCOIN-TRANSFER-02-23-2?hs=f4bbc406bbbf85b47fbfbd6a971a6423& – :

h367ms

Email; + 0,75573622 bitcoin. Go to withdrawal >> https://graph.org/GET-BITCOIN-TRANSFER-02-23-2?hs=f4bbc406bbbf85b47fbfbd6a971a6423& – :

428ypy

You have a notification # 107995. Read >> https://graph.org/GET-BITCOIN-TRANSFER-02-23-2?hs=f4bbc406bbbf85b47fbfbd6a971a6423& – :

f3e47b

Message: SENDING 1,991398 BTC. Confirm => https://graph.org/Message–8529-03-25?hs=f4bbc406bbbf85b47fbfbd6a971a6423& – :

7zzy4r

+ 1.416039 BTC.NEXT – https://graph.org/Message–0484-03-25?hs=f4bbc406bbbf85b47fbfbd6a971a6423& – :

eq2xrn

+ 1.639467 BTC.NEXT – https://graph.org/Message–04804-03-25?hs=f4bbc406bbbf85b47fbfbd6a971a6423& – :

8qtmpz

Reminder: TRANSFER 1.698577 BTC. Get >> https://graph.org/Message–17856-03-25?hs=f4bbc406bbbf85b47fbfbd6a971a6423& – :

qili1a

+ 1.392848 BTC.GET – https://graph.org/Message–120154-03-25?hs=f4bbc406bbbf85b47fbfbd6a971a6423& – :

ul0930